Ensuring Product Excellence

Our systems receive extensive quality and reliability testing to ensure the highest performance end products.

Thousands of tests + hundreds of hours = one good server

Each server undergoes a gauntlet of over 2,000 full-life-cycle tests in 9 test categories to fulfill the most stringent quality standards before it leaves the facility and reaches our customers.

Signal Integrity Simulation

Full-wave electromagnetic field simulation is conducted on server components at DC-80GHz to analyze signal transmission, reflection and matching characteristics of components’ dimensional structures.

Data Center Business Simulation Test

R&D and testing for data center concepts, such as water-cooled cabinets and modular data centers, are conducted here. Also featured here is the world's largest pressure aging test line that can support simultaneous stress testing of 6400 servers for up to 50 hours.

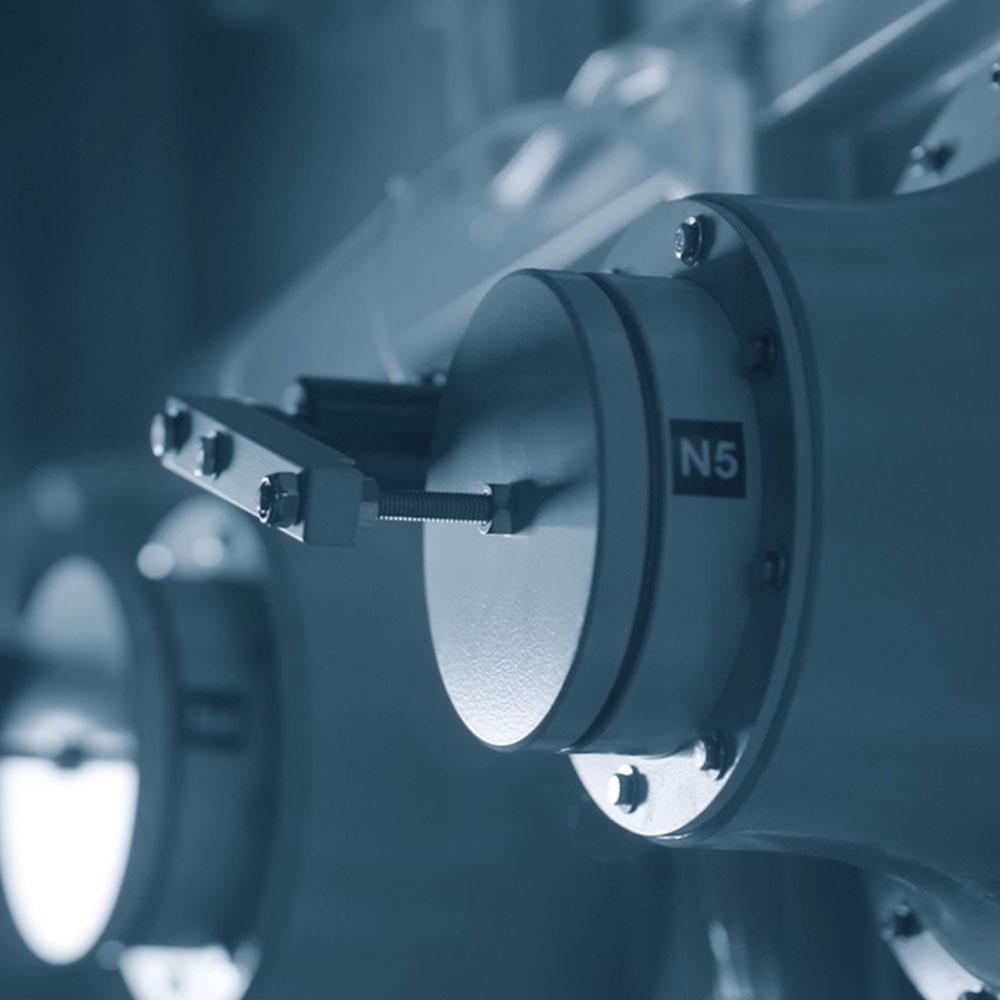

Mechanical Environment Test

Each product undergoes thousands of shocks and drops to simulate various transportation conditions via air, road and sea. Tests also accounting for extreme conditions include an earthquake simulation test at seismic intensity exceeding the earthquake resistance standard for general buildings.

Climatic Environment Test

Products undergo eight climate test conditions including HALT, high and low temperature, high and low humidity, temperature and humidity cycles, and thermal shock. The assessment is involved in design changes, mass production process abnormalities, and finished product verification stages.

Power Integrity Test

The industry's first full-process, automated power integrity (PI) test platform simulates DC and AC simulation for optimizations to the system design. Dynamic response test 40% compared to standard pressurization.

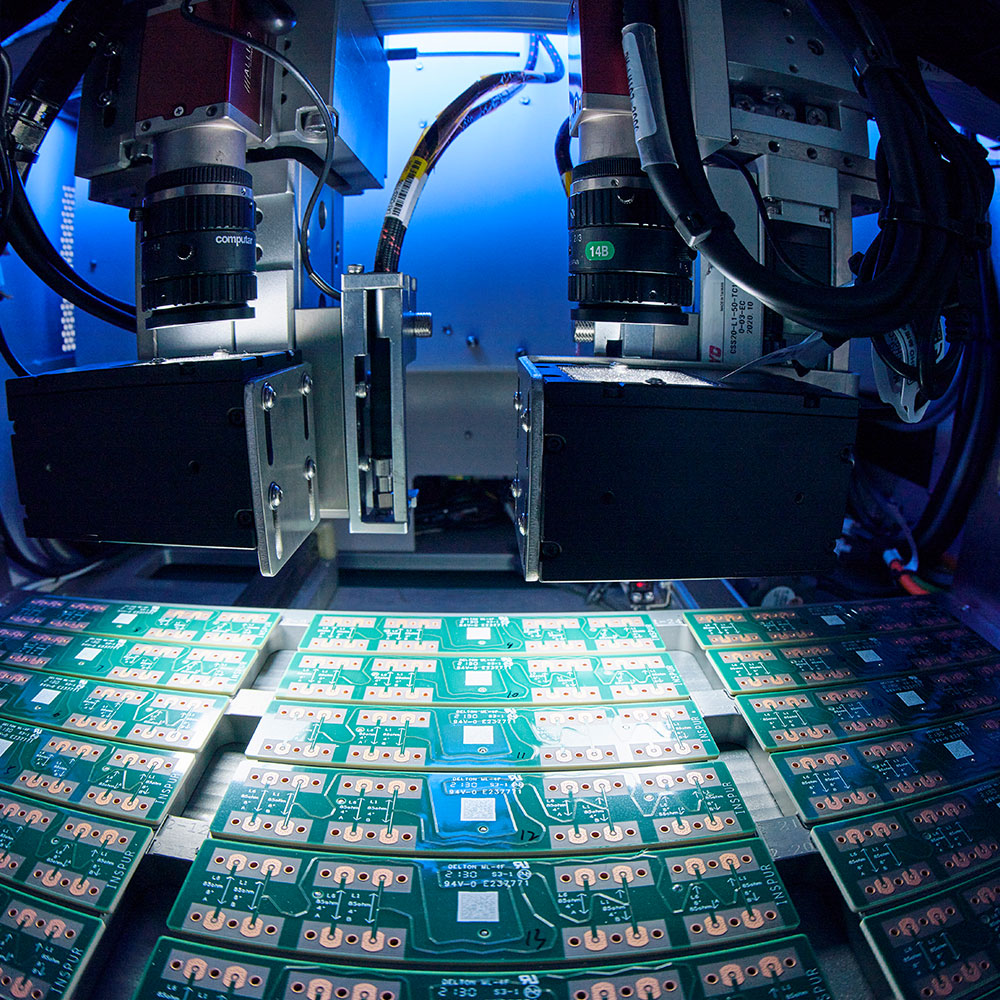

Failure Analysis Test

A full failure analysis panel of 46 tests in 6 categories includes electrical performance testing, slicing and microanalysis, corrosion testing, PCB, component failure analysis, mechanical analysis and board reliability test.

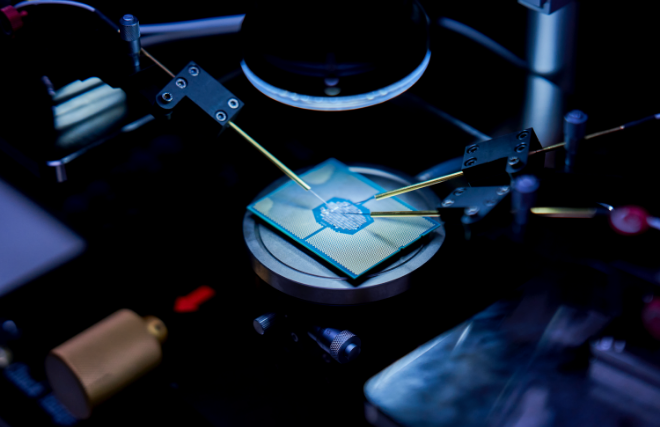

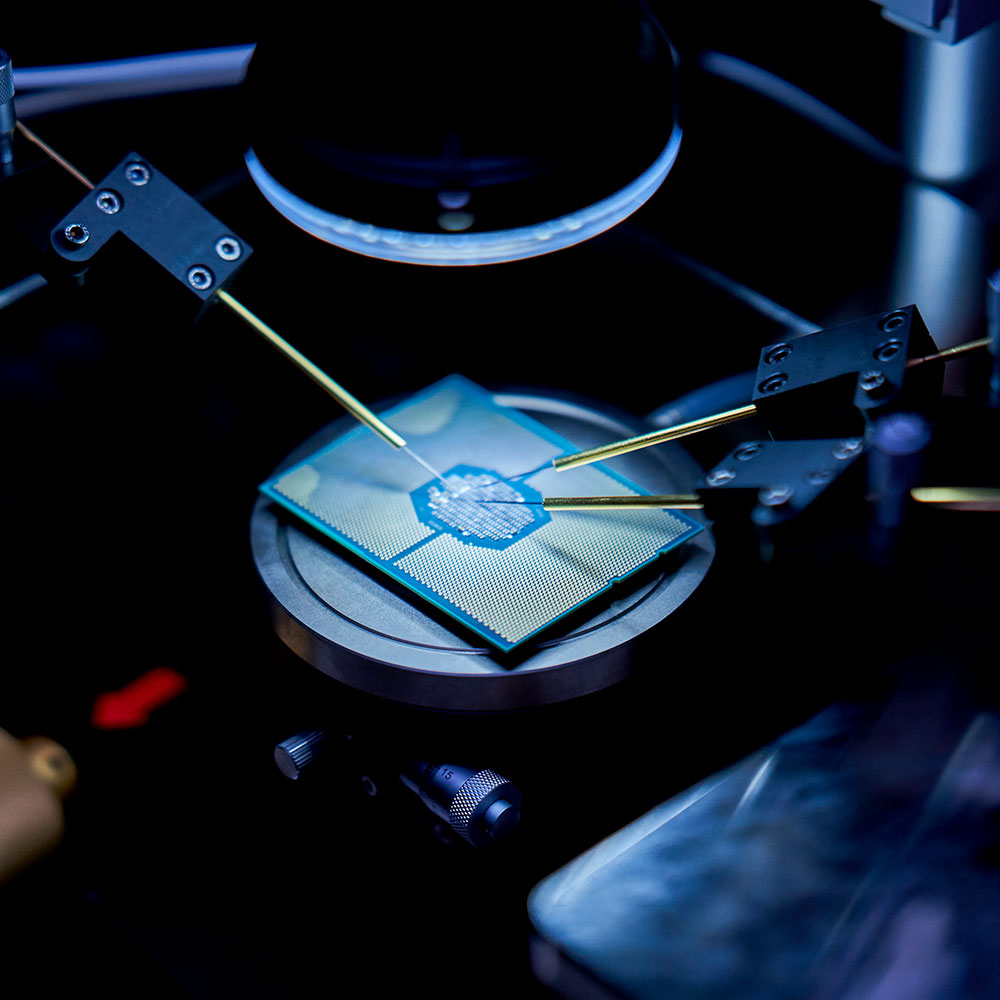

Signal Integrity Test

The industry's first fully automatic press-contact signal integrity (SI) test platform has a positioning accuracy down to the μm level, thereby leading to a tenfold increase in efficiency.

Electromagnetic Compatibility Test

This is used for testing and near-field analysis of EMC by simulating conditions like static electricity, lightning strikes, voltage transients, power-frequency magnetic field interference and radiation emission.

Structural Heat Dissipation Test

A product’s structural reliability is tested via sag testers, wind tunnels, and high and low temperature test chambers. Accurate air flow resistance measurements ensure the cooling design meets fluid mechanic, heat dissipation, and power efficiency standards to reduce energy use by 8%.

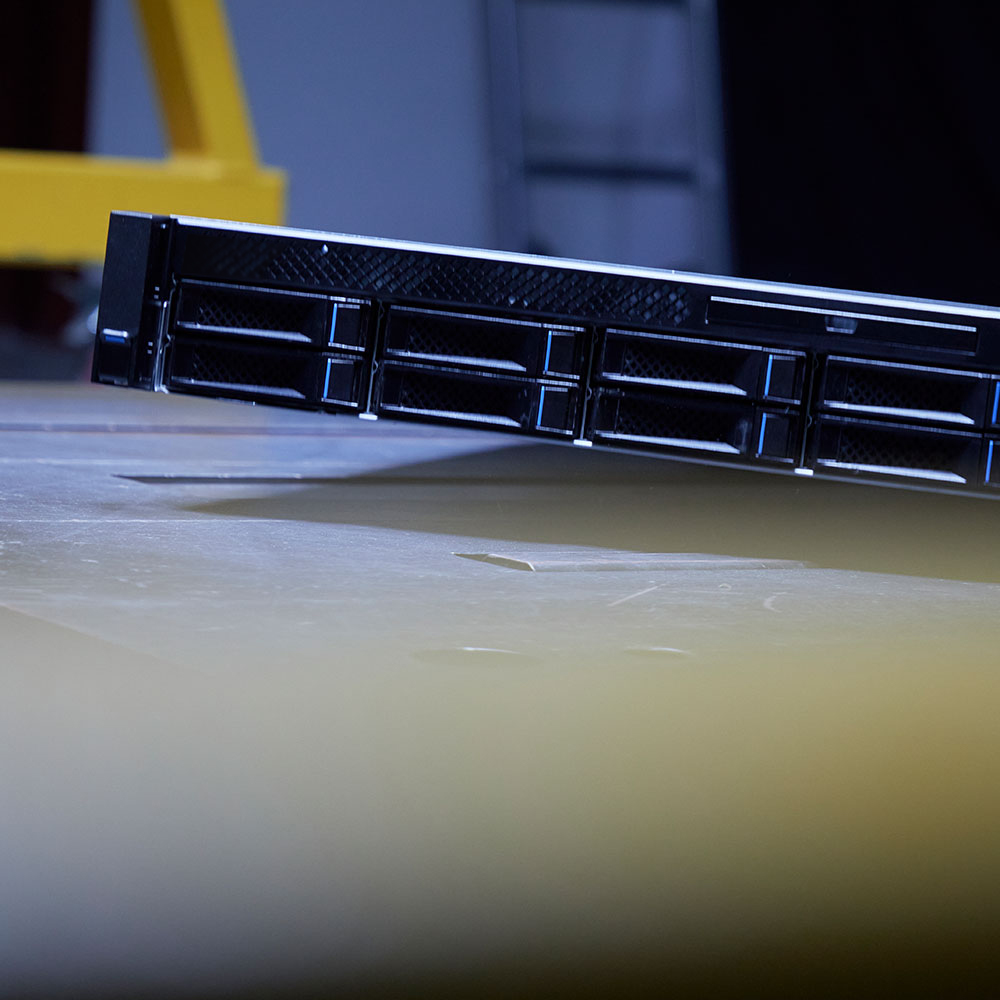

Finished product: the ultimate server

Through meticulous engineering, fine-tuning, testing and labor, a server is born. This server represents the Aivres promise: to deliver the finest possible product, a powerful tool for buniess transformation, and a peace of mind for the customer.